Scale Model of the Space Shuttle

This large scale project was an exercise in communication and time management for incoming college freshman. Over the course of the class, we were to build a scale model of the space shuttle using popsicle sticks, hot glue, and lots of estimated dimensions.

The space shuttle model was a semester long project for the college success course with Dr. Bradley Wall in Fall 2017.

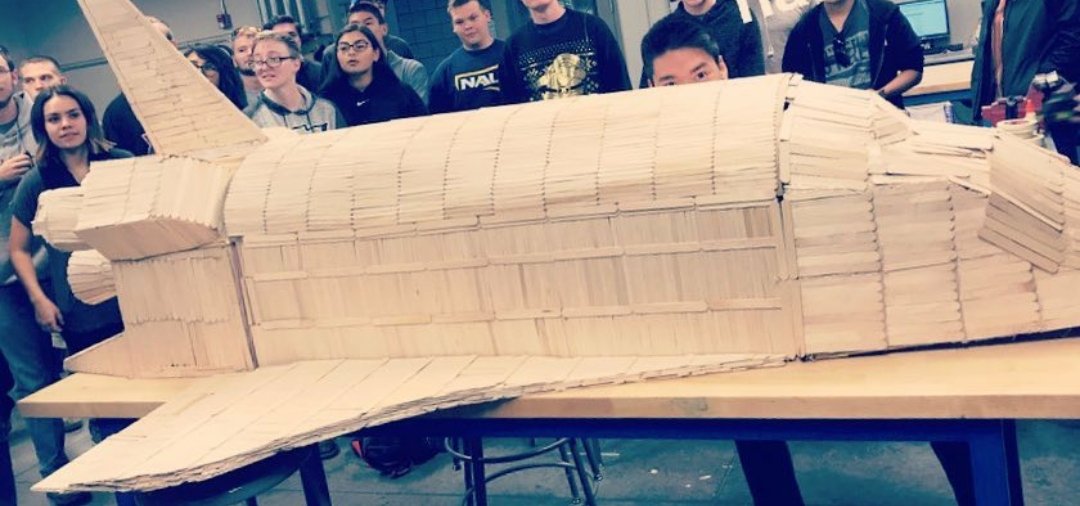

Fully assembled space shuttle model.

Foam padding and base structure of the rear section.

The project model was approached by first defining a scale and total length of our model, which was determined to be a 1:13.5 scale, resulting in a 9 foot model. Sub teams were created to divide the model into multiple buildable sections, such as the different sections of the fuselage, each wing, the main engines, and even the body flap. From there, each team set to work dimensioning their section, confirming interfacing with other teams, and beginning to build. Building was by far the most time consuming, taking most of the semester to cut each individual popsicle stick to length, sand the cut edges, and hot glue into place. Foam padding was used to create a more sturdy base for large sections, namely the cargo bay and the back wall of the rear section that carried the full weight of the main engines.

My individual role in this project included leading a team of four to build the rear section of the space shuttle fuselage. This part was particularly important to the success of the model. Many smaller parts were dependent on and attached to the rear section. Each surface of the rear section was built separately using popsicle sticks cut to length and hot glued to fill a 2D sketch of the respective surface, then hot glued to create a 3D shape.

Due to team complications, the rear section was barely finished. One sidewall was weakly attached to cover the open interior, and was the first piece on the project to come loose. However, the final result was one of the largest and most satisfying projects I’ve done to date. The scale model was displayed outdoors on campus across two large benches and disposed of at the end of the day.

Although done in my first year of college, I often find myself returning to a few key lessons I learned early on about engineering through this project. First and foremost, how communication and putting in hard work can make or break a project. My team for this project was particularly disinterested, and I found myself trying to pick up a lot of the slack on the build, as well as talking extensively to other teams to ensure properly fit parts. At the time I didn’t question it, and although I enjoyed the project overall I was unsatisfied with my team. After a few short years I have learned how to find a team balance I thoroughly enjoy, ask for help, and speak up when there’s conflict.

UNIV 101: College Success with Dr. Bradley Wall, class of Fall 2017.

Thumbnail image by Jean-Philippe Delberghe on Unsplash.

A quick walk around of the fully assembled space shuttle model. Assembled in the on-campus machine shop as a class, with Dr Bradley Wall talking in the background.