Artemis Mining Concern: Lunar Regolith Crushing Mechanism

The focus of Artemis Mining Concern (AMC) lies in the primary stage of lunar mining where newly excavated hard rocks will be sized for further processing. The crushing of lunar regolith is the first step in the process of mineral refinement and the products can be used for lunar or terrestrial purposes. The materials produced from lunar mining will make building on the lunar surface far more rapid and cost-effective, as transportation time and costs for these materials sourced from Earth are eliminated. AMC is taking the first step towards realizing lunar mining by designing a primary rock crusher capable of reducing the size of simulated lunar regolith.

The Artemis Mining Concern is a year long senior capstone to be prototyped and tested in December 2021. Due to a decrease in class size and the ambitious scope of the previous project PELE, I joined the team for the second design semester.

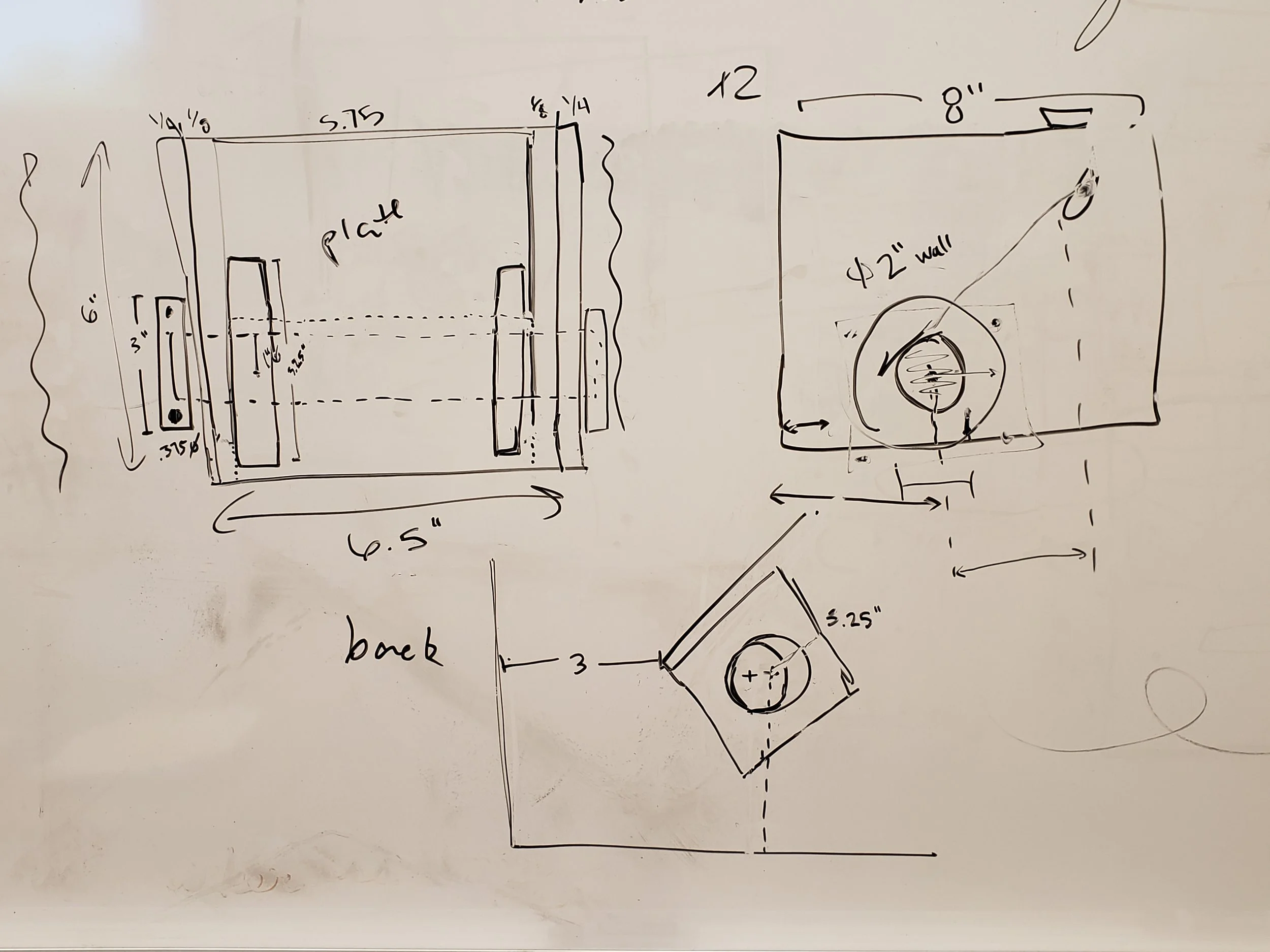

Detailed sketch with dimensions of the crushing mechanism.

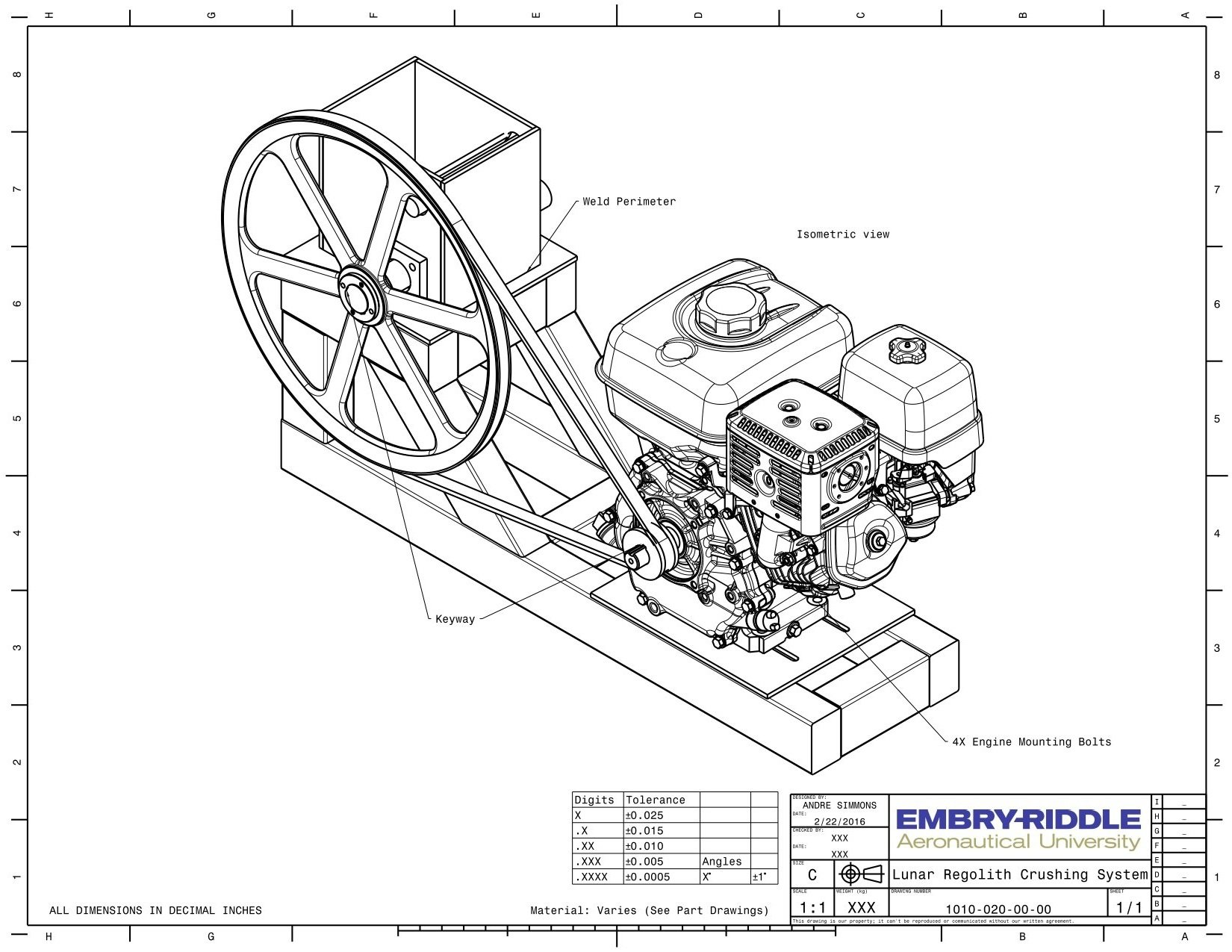

Full LRCS assembly drawing.

Justin Evans (left) and Grey Trotter (right) in the machine shop, labeling parts before wrapping up for the day.

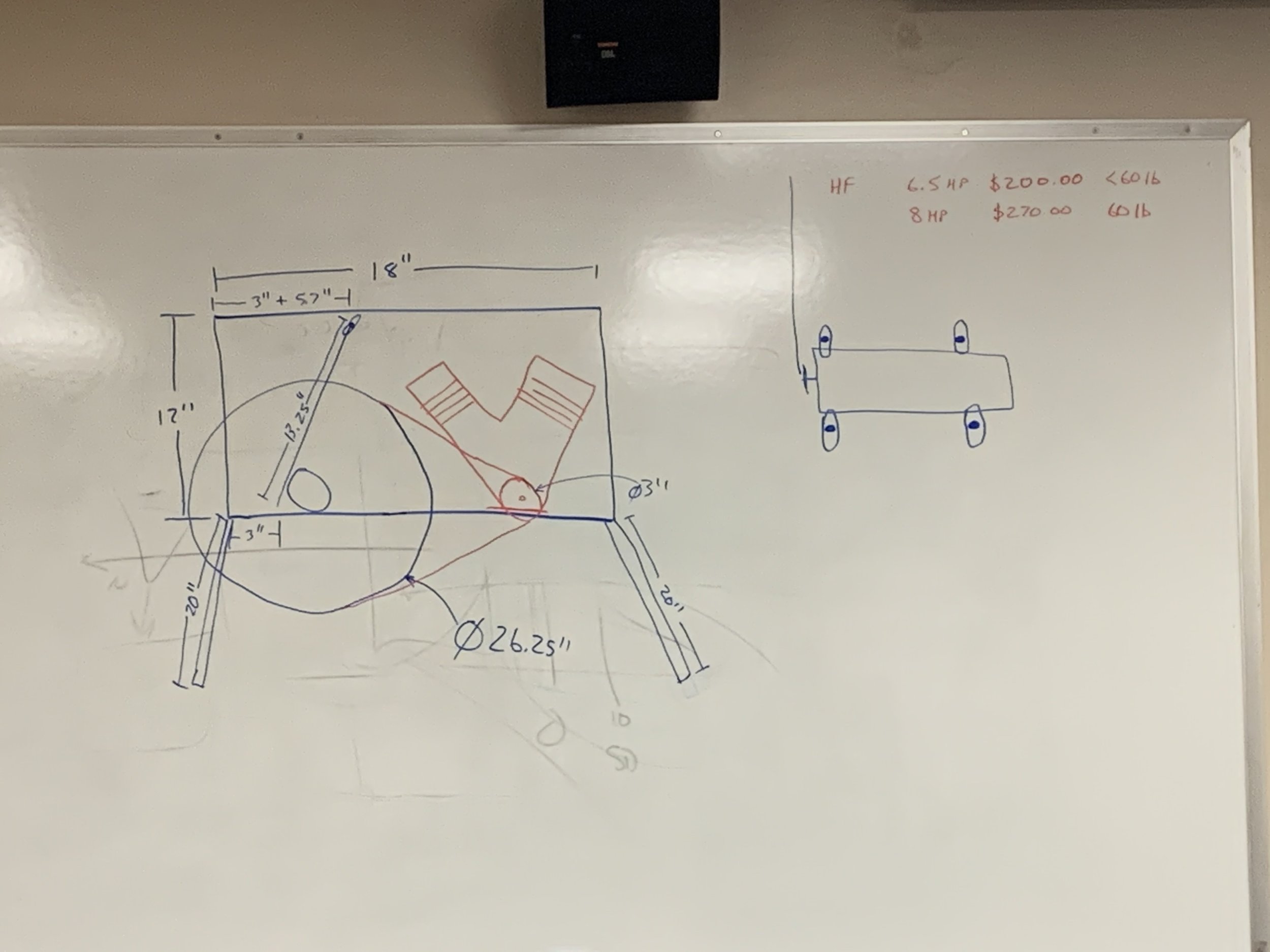

Artemis Mining Concern is designing and creating the Lunar Regolith Crushing System (LRCS) to crush basalt samples no larger than 6”x6” into smaller pieces no larger than 6”x3”. Basalt was chosen as the Earth-equivalent of rocks found on the Moon by density. To accomplish this, a rotating eccentric shaft moves a steel plate back and forth with the force necessary to crush the basalt through an opening. This shaft is turned by a transmission subsystem connected to a gasoline engine, all mounted to a steel structure. The team was divided into sub-teams for each of the three subsystems, each with a member strong with CATIA and a member strong with ANSYS and structure analysis. Other tasks were assigned similarly, based on work load and strong suits.

My individual role on the Artemis Mining Concern team has included intense CATIA models and manufacturing drawings for the crushing mechanism and housing, as well as communicating with other team members responsible for other subsystems to confirm the dimensions of interfacing parts. Other responsibilities to date include writing and editing documents and aiding in the fabrication of the LRCS.

The expected results of Artemis Mining Concern are to fabricate the designed LRCS, test, and verify the objectives and requirements created at the start of the project. Tests include verifying the system has the energy required to crush basalt without becoming significantly deformed in the process. As of Oct 2021, AMC is on track to accomplish this.

Because of this project, I have gained valuable practice in 3D modeling software and skills in the on-campus machine shop including the waterjet and basic welding techniques. The team lead of Artemis Mining Concern, Dan Keaty, has shown me what it means to be a dedicated, organized leader that is aggressive with time management. I have also become much more proficient in creating and giving professional, informative presentations and communicating with both my team and different departments around campus including safety, facilities, and the machine shop.

Full team: Dan Keaty, Kevin Hall, Andre Simmons, Justin Evans, Danny Mahan, Emily Drozynski, and Grey Trotter.

AE 445: Spacecraft Detail Design course with Dr. Kaela Martin and Dr. Kathy Wood.

Com 430: Advanced Technical Communications II course with Dr. Erin Twal Cromer.

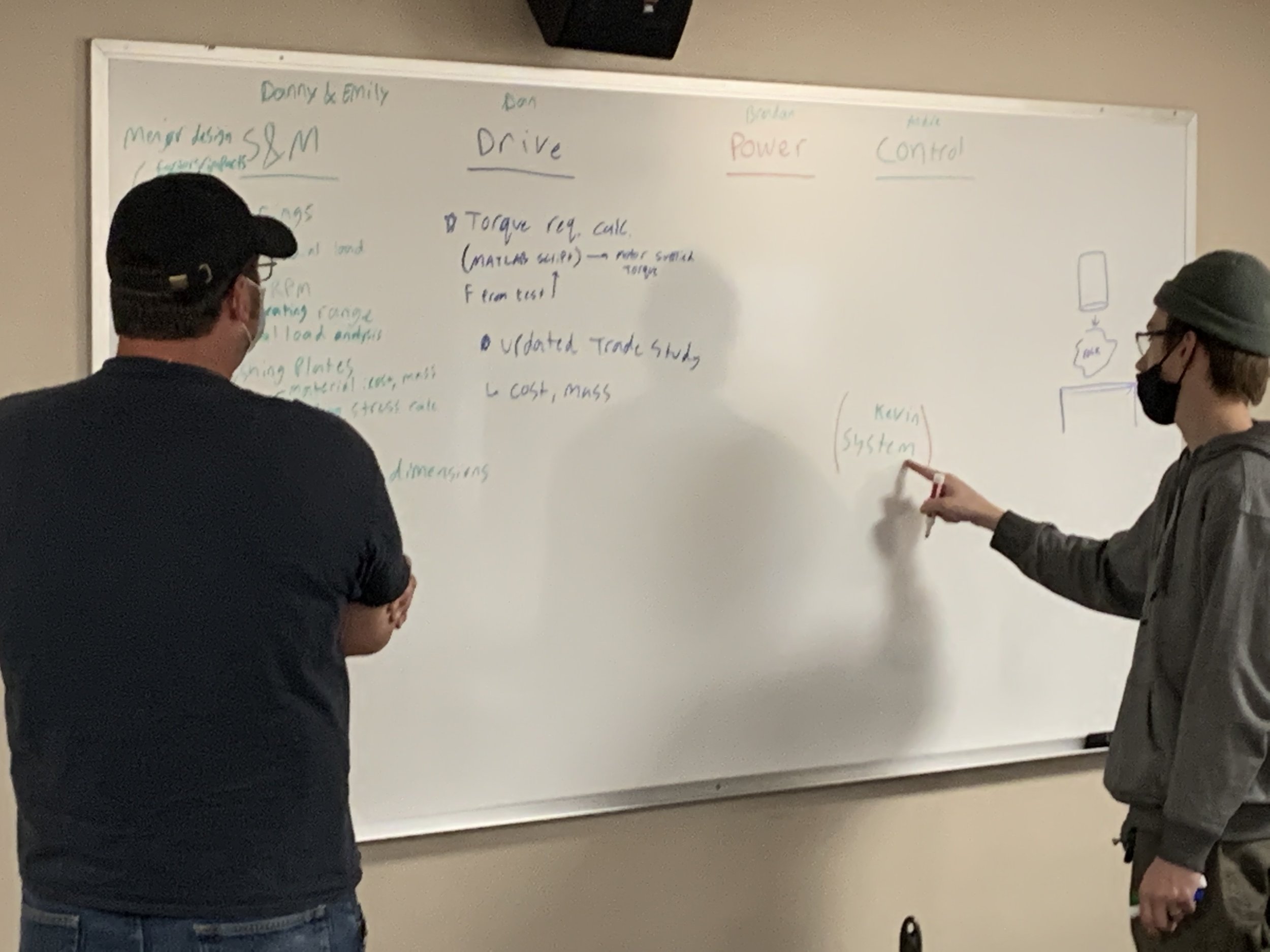

Kevin Hall (left) and Dan Keaty (right) discussing the LRCS during the prelim semester. This was later simplified.

Concept design of the LRCS. Engine in red with a large flywheel and belt, and the reciprocating plate.

Using the water jet to cut the reciprocating plate out of quarter inch steel, with the help of machinist Patrick David.

Using the band saw to cut crusher housing walls.

Kevin Hall welding the support structure.

Fully welded support structure, not including the mounting plates for the engine or crushing mechanism.