Pele: A Lunar Solar Smelter

For humans to successfully develop colonies on bodies other than Earth, a system is needed that can process ore mined on the moon, without requiring fuel to be shipped in. PELE is a solar smelter design that focuses on creating an efficient process for safely smelting minerals on the Moon while tackling potential problems such as heat losses, sun tracking, insulation of components near extreme temperatures, and moving loose material through a system.

The PELE smelter was a year long senior capstone to be prototyped and tested in December 2021. However, due to a decrease in class size and the ambitious scope of the project, the PELE team was dissolved after the preliminary design semester.

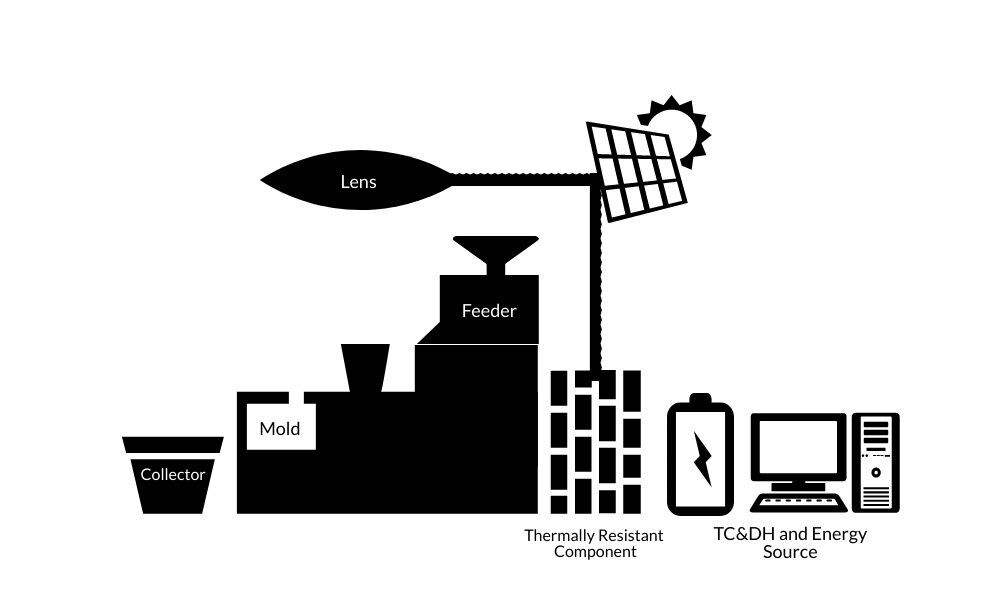

Preliminary graphic of the full assembly design.

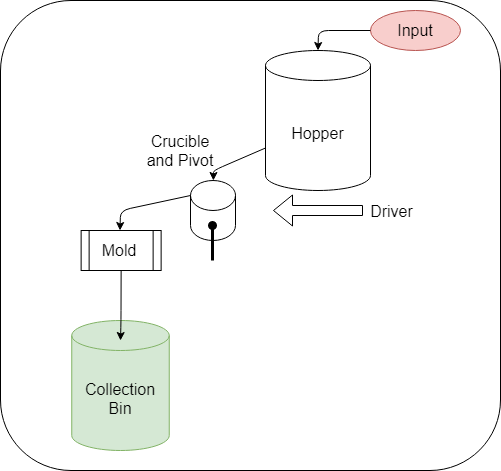

Depiction of the Mass Flow Subsystem.

Capstone Team Lead

Being team lead for our capstone project brought on challenges I otherwise would not have faced. It has taught me to be more honest with my colleagues and expect the same in return, as well as how to handle time management and hit deadlines in a group dynamic. This role has made me more communicative with my professors and more comfortable with asking questions and for assistance, which I plan to bring with me into the industry.

Pictured left to right: Grey Trotter, Britney Alvarez, Trey Brown, Justin Evans, Maverick Thigpen

PELE uses heat flux through a Fresnel lens, to be tested on Earth using copper to simulate the heat intensity needed on the lunar surface. Mass enters and exits the heated crucible through an automated mass flow subsystem, and uses a pivoting arm with attached solar panels and lens for optimizing flux and tracking the Sun. To accomplish this, each member of the team was responsible for designing a different subsystem and ensuring the compatibility with other subsystems, as well as reporting on their area of expertise in documents and raising major design changes to the team as a whole.

My individual research was primarily on the mechanics of the Mass Flow Subsystem. This included moving the copper input through a hopper into a crucible, pouring the melted copper into a mold, and releasing the cooled copper from the mold into a collection bin. This process had to be fully automated and repeatable. A variety of engineering elements went into accomplishing this including material analysis and sensor trade studies.

The final outcomes of the PELE project included in depth research on sensors and electrical components, heat transfer, solar processes, and mechanical design, as well as a fully formed preliminary design that was otherwise approved to continue into the fabrication process. A critical design review presentation to a panel of professors and our peers, as well as a final document summarizing the PELE project, were completed at the end of the semester.

Because of this project, I have grown significantly in writing technical documents and performing trade studies, designing and optimizing components, and working in a team setting to ensure all parts of the system are compatible. I have also become much more proficient in creating and giving professional, informative presentations for a variety of audiences.

AE 427: Preliminary Design course with Dr. Ron Madler, Dr. Kathy Wood, and Dr. Daniel White.

Com 420: Advanced Technical Communications with Dr. Erin Twal Cromer.

Focus length test of the Fresnel lens.

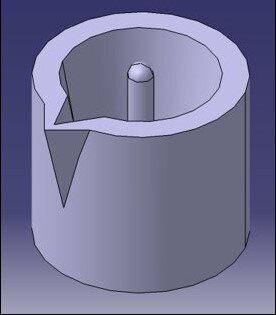

CATIA model of the custom crucible, including a pouring divot and center rod for internal heat detection.

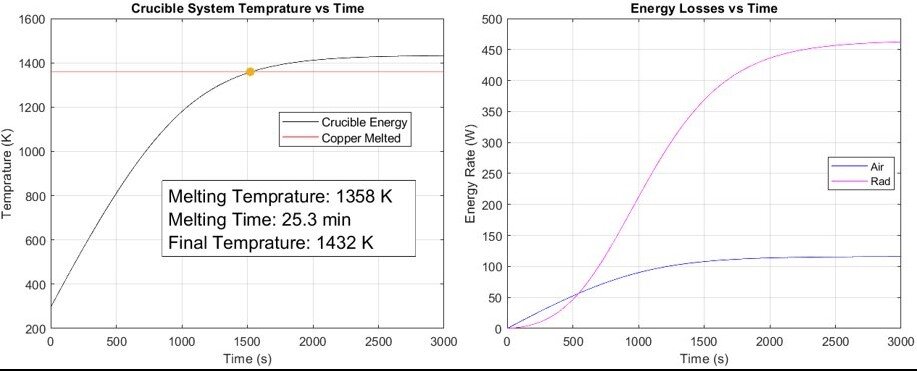

Evidence the system will heat the copper to the melting temperature (left) and the predicted heat losses (right).

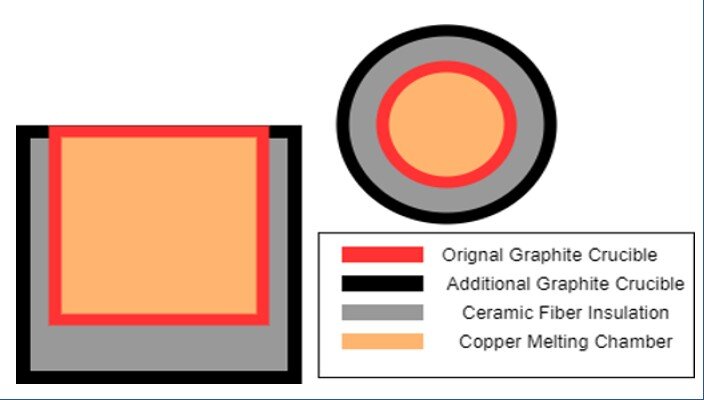

Depiction of the layers of material in and around the crucible.